Building Design speaks to Hugh Broughton and Robert Songhurst about the challenges and innovative solutions behind the restoration of Sheerness Dockyard Church. From the reconstruction of its roof to the integration of sustainable features, they discuss how careful specification choices and strategic collaborations brought this historic landmark back to life

For nearly two centuries, Sheerness Dockyard Church has stood as a testament to Britain’s naval history, its architecture reflecting the grandeur and resilience of its time. Initially constructed in 1828 to the designs of George Ledwell Taylor, the church played a central role in the lives of dockyard workers, providing a place of worship at the heart of one of the country’s great naval shipyards. However, the passage of time was not kind to the building. After suffering two catastrophic fires – one in the 1880s and another in 2001 – the church was left roofless and in ruins, its cast iron columns weakened and its masonry exposed to the elements.

The challenge of restoring this historic structure was immense, requiring a balance between conservation, innovation and functionality. Hugh Broughton, director at Hugh Broughton Architects, and Robert Songhurst, associate at Hugh Broughton Architects, explain that every design decision needed to respect the building’s rich past while ensuring its future sustainability.

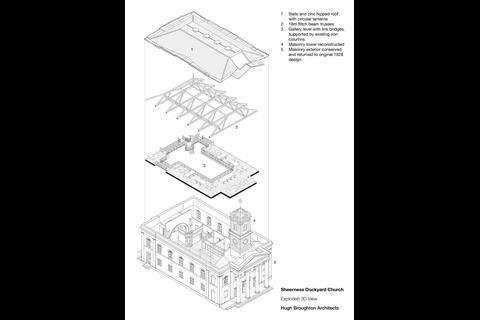

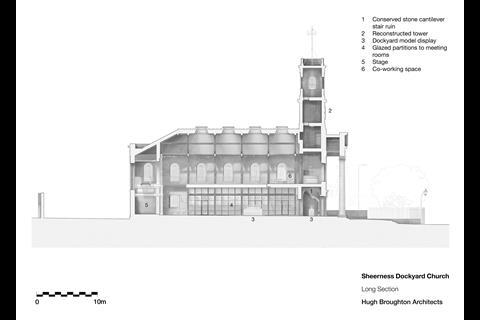

One of the most striking interventions in the restoration project was the reconstruction of the roof. When work began, the church had no roof at all, and the fire-damaged iron columns that once supported it could no longer bear structural loads. Despite their compromised strength, these decorative fluted columns remained an essential feature of the space and needed to be retained.

The solution lay in an innovative flitch truss system – a hybrid structure with a steel core flanked by glued-laminated (glulam) timber elements. This design allowed the roof to span from wall to wall without relying on the weakened columns while maintaining a visual connection to the church’s historic character. The trusses also served a secondary purpose, concealing vital services such as lighting fixtures and smoke detectors within their structure, ensuring that modern interventions did not detract from the building’s architectural integrity.

Beneath the ruined structure, the original timber floor had long since decayed, with trees growing inside the exposed foundations. The restoration team faced the task of reconstructing a new floor while maintaining the building’s historic fabric. The chosen solution was a concrete floor slab with embedded underfloor heating, an approach that provided both structural stability and efficient thermal performance. Given the church’s vast masonry walls, underfloor heating proved ideal, gently warming the space and allowing the retained heat to radiate over time. Additional radiators were installed on the first floor, creating a simple yet effective heating system.

Despite the need for modern comfort, the team sought to maintain as many original passive environmental systems as possible. One of the most remarkable discoveries during the project was a series of Tobin tubes, a 19th-century innovation designed to channel fresh air into the building without disrupting its architectural form. These concealed ventilation channels, built within the window sills, were reinstated to allow improved air circulation without visible modern alterations.

In addition, the building’s leaded windows – historically significant elements – were carefully reconstructed based on historic drawings. Special opening hoppers were incorporated, further enhancing natural ventilation. Though a mechanical extract system was added, utilising the church’s tower to remove excess heat, the design prioritised passive strategies wherever possible.

Budget limitations often dictate the course of a restoration project but, rather than seeing financial constraints as obstacles, the team used them as opportunities for creative problem-solving. One of the most significant cost-saving decisions involved the church’s parapets. Initially, these tall masonry features were clad in stone, a material that proved too expensive for the restoration. Instead, a Roman render was applied – a durable and visually sympathetic alternative that reinstated the building’s original silhouette without exceeding the budget.

Another unexpected challenge emerged with the church’s tower. Fire damage had severely weakened the internal brickwork, effectively turning the tower into a chimney during the 2001 blaze. After careful assessment, it was determined that the only viable solution was a complete dismantling and reconstruction, using as much salvaged material as possible. Each piece of masonry was meticulously numbered and catalogued before being reassembled, ensuring that the historic character of the tower was preserved while securing its structural integrity for the future.

Sustainability and community involvement were at the heart of the restoration. The main contractor, Coniston, made a concerted effort to source materials and labour locally, reducing transport emissions and supporting the regional economy. Apprentices from the local community were employed, helping to foster new skills and create employment opportunities.

Even the structural steel beams required for the tower’s reconstruction were sourced just a short distance away, from a facility within the Sheerness Dockyard itself. These efforts minimised the project’s carbon footprint and reinforced its connection to the dockyard’s industrial heritage.

The success of the Dockyard Church restoration was due in no small part to the collaborative spirit of the project team. Architects, structural engineers, conservation specialists and contractors worked closely with the Sheerness Dockyard Trust to navigate the complexities of the build. The use of advanced digital modelling, including highly detailed Revit models, allowed for precise planning and visualisation, ensuring that both historical accuracy and contemporary functionality were achieved.

More than just a building, the restored Dockyard Church now stands as a beacon of regeneration for Sheerness, transforming from a ruin into a vibrant community space. Through a careful balance of conservation, innovation and sustainability, the project has not only honoured the past but also secured a future for this remarkable piece of Britain’s naval heritage.

Project details

Architect Hugh Broughton Architects with Martin Ashley Architects

Client Sheerness Dockyard Preservation Trust

Structural engineer Hockley & Dawson Consulting Engineers

M&E consultant Harley Haddow

Quantity surveyor PT Projects

Project manager Glevum Consulting

Approved building inspector STG Building Control (for Swale Borough Council)

Acoustic consultant Ramboll

Landscape architect Marian Boswall Landscape Architects

Lighting consultant Sutton Vane Associates

Model interpretation AFSB Associates

Main contractor Coniston

CAD software Revit

Start on site November 2020

Completion June 2023

Gross internal floor area 875m²

Construction cost £5.7m

Construction cost per m² £6,500

Annual CO2 emissions 40.8kgCO2/m² (estimated)

Concrete ground floor with inset original tiles, terrazzo to service duct covers, and column surrounds Design assistance by David Bennett Associates, realisation on-site by Lazenby Contracts

Glulam/steel hybrid flitch beam structure Design by Hockley and Dawson

Acoustic ceilings Russwood

Glazed screens and doors Optima Systems (117 Plus Shoreditch, Technishield where fire compartmentation was required)

Engineered timber flooring Boen (Oak Chaletino plank, white live natural oil)

Limewash-type paint to interior surfaces Rose of Jericho

Roof insulation Rockwool

Slate Glendyne – Canadian, as a cost-effective alternative to Welsh

Zinc VM Zinc

Circular rooflights Roofglaze

Bespoke metal balustrades and repairs Installed by Paul Dennis Metalworks

Bespoke spiral stair Spiral UK

Ladders and hatches for access to roof and tower Surespan

Clock restoration Smiths of Derby

Interior lighting design Sutton Vane Associates

Postscript

Calling manufacturers! Gain a competitive edge by understanding what architects value most when making their specification choices. Hear from Hugh Broughton and Robert Songhurst as they share insights on early engagement, technical support, and building successful supplier partnerships. Watch the webinar here.

1 Readers' comment