Even where specialist advice is available, a working knowledge of regulations and performance is crucial when you want to make the right design decisions

When it comes to fire performance technology architects should not leave it all up to the fire engineer. Knowing the pros and cons of various construction materials and how they can affect the design is essential.

Detailed, chunky timber structures, for instance, can perform well by slowly forming a char layer. However, slender timber is generally protected by fire-rated board and great care needs to be taken on the detailing of this and on maintenance over its lifetime.

Meanwhile, the fire performance of concrete — with its variety of mixes and formulations — is hard to define.

Steel’s great advantages are that it is non-combustible and that there is a tremendous amount of research into how it performs in a fire. “The good thing about steel is that we know a lot about it and how it behaves,” says Florian Block, senior structural fire engineer at Buro Happold. “This means we can be confident in the way it performs.”

Building Regulations

The Building Regulations for England and Wales set out the legal obligations for building designers. These functional requirements outline what must be done, but do not address how to achieve this. The government publishes a set of “approved documents” to explain how these requirements can be met. For fire, the relevant publication is Approved Document B (2006).

An example of a functional requirement that covers structural stability in a fire is that “the building shall be designed and constructed so that, in the event of a fire, its stability will be maintained for a reasonable period”.

The regulations do not specify what a “reasonable period” is, but Approved Document B contains guidance on this. Structural fire resistance periods vary between 30, 60 and 90 minutes, according to the occupancy and the height of the building, and requirements change at 5, 18 and 30 metres. For example, an office that is less than 18m tall must maintain structural stability for 60 minutes during a fire. This can be reduced by 30 minutes if a sprinkler system is installed.

British Standard 9999: the Code of Practice for Fire Safety in the Design, Management and Use of Buildings is an alternative to Approved Document B. It seeks to allow the development of solutions based on an understanding of the causes of risk to life and how these can be mitigated.

It classifies buildings according to a risk profile based on occupancy, fire growth rate, ventilation conditions and building height. It also introduces a new height category for buildings taller than 60m and generally allows more attractive trade-offs for automatic sprinklers installation and automatic fire detection than the approved document does.

When to call an expert

This depends on the complexity of the building and the form of construction — the more unusual the structure, the more useful expert fire risk analysis can be in achieving an appropriate level of fire-protection. Where prescriptive guidance may be overly onerous (for example composite steel-framed buildings) or difficult to apply directly, fire engineering can be used to reduce the amount of applied fire protection required.

“With a simple building that has a standard structure, it might well be that an architect in conjunction with a structural engineer and specialist manufacturers might develop an appropriate strategy,” says Alan Wilson, senior engineer at Arup Fire. “But when dealing with complex designs, you’re more likely to require expert advice.”

A basic understanding of fire regulations can help architects decide how much specialist advice they require. Ideally, fire experts should be involved near the start of the project. Wilson says that this typically results in greater design freedom and ultimately a more cost-effective solution, despite the cost of having consultants involved from the onset.

Fire protection materials

To meet requirements for structural stability in the Building Regulations, a multi-storey, steel- framed structure will usually require fire protection.

New products and increased competition mean that the cost of fire protection has come down a lot over the past 20 years. The past decade has seen a huge swing towards the use of thin film intumescent coatings in new buildings. Once a niche product, these accounted for more than 70% of the market in 2010, according to the Construction Markets survey carried out each year on behalf of the steel construction sector. This was followed by board (25%) with a relatively small percentage of spray and other niche products.

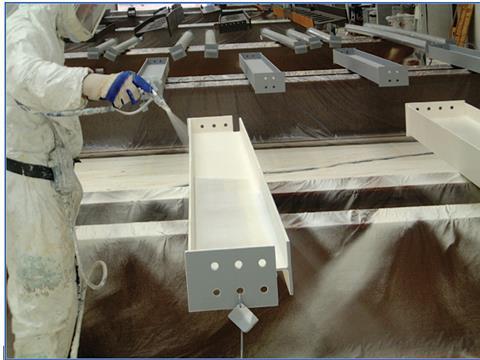

Most intumescent coatings are applied on site, although off-site application has increased in popularity in recent years and now accounts for about a third of total use. Intumescent coatings are paint-like materials that expand when heated to form a char with excellent insulating properties. They can be water based, which is mostly used on site, or solvent based, which dominates the off-site market.

The more unusual the structure, the more useful expert fire risk analysis can be

If applied on site, these coatings can be used to create decorative finishes — although this may cost more. Aesthetic finishes are also possible when applying a coating off site, however this is more problematic because of the difficulty of repairing any damage on site to the same standard.

Off-site application of intumescent coatings can be more expensive in terms of up-front costs than on-site alternatives, but can have benefits where site access is difficult or restricted and may save costs in the long run.

Boards are available in two types: heavy duty boards, which take decorative finishes for aesthetic use; and lighter, cheaper boards for situations in which aesthetics are not important.

Sprays are lightweight products that are easily and cheaply applied, but are not decorative. Their use has declined in recent years, but they are still used — particularly in large buildings that require high periods of fire resistance.

Guidance

The Association for Specialist Fire Protection offers extensive guidance on specifying fire protection systems. This includes the publication Ensuring Best Practice for Passive Fire Protection in Buildings, which describes itself as “guidance intended to offer architects, designers, constructors, building occupiers and others, effective and feasible recommendations and selection criteria for the use of passive fire protection systems in buildings”.

What architects should know about fire protection of steel structures

Florian Block, senior structural fire engineer at Buro Happold offers these guidelines:

- Steel structures often behave better in fire than suggested by standard fire tests, because of the development of alternative load paths. On the other hand, complex and unusual steel structures might behave worse than standard fire tests suggest, owing to thermal expansion of the surrounding materials. These factors can be assessed by structural fire engineers, and this can deliver significant safety and aesthetic benefits and cost savings if considered early.

- If specifying intumescent coating as fire protection, architects need to be aware that intumescent paint expands to many times its thickness when heated up. Since it only works properly if it is able to do so, architects need to leave a gap around the structure, which is often overlooked. The size of the gap depends on the fire resistance period and the type of intumescent coating used. The Association for Specialist Fire Protection recommends a gap of 50 times the initial paint thickness, which would normally lead to gaps of 25-75mm unless specified differently by the intumescent paint manufacturer.

- In cases where a compartment wall is built on the under-side of a steel beam, the wall should continue past the beams to the underside of the floor slab, unless the beam is protected to at least the same standard as the compartment wall using fire protection other than intumescent paint.

- Guidance documents such as Approved Document B or BS9999 suggest roof structures do not require fire protection. While this might be true for the top storey of multi-storey buildings, it is not always true for complex roof structures covering larger assembly buildings such as exhibition halls, stadiums and arenas. In these buildings, the fire protection requirements of the roof structure need to be carefully assessed by a structural fire engineer.

CASE STUDY: Project Green, Nottingham

Fire engineer Arup

Architect Maber Associates

In this office building, which is still under construction, Arup was able to reduce the amount of fire protection on the outside of the building from what would have been required if it had followed prescriptive guidance. As a result, it was able to install far more glazing.

The building is greater than 30m in height. It is served by three staircases and incorporates a central atrium void that connects the ground level to all upper areas of the building. An important design aspiration was to include large areas of glazing on the external facade and maintain open connections with the internal atrium space.

Crucial aspects of the fire engineering design included an assessment of the risk of fire spreading externally and determining realistic fire sizes based on sprinkler activation. This facilitated the adoption of a 100% non-fire-rated facade. An alternative arrangement for ventilation of fire-fighting shafts at basement level removed the need for dedicated smoke shafts.

A structural fire engineering assessment demonstrated that 60 minutes of fire resistance was sufficient to satisfy the functional requirements of the building, compared with the prescriptive recommendations, which would have required 120 minutes of resistance.

Use of a mechanically assisted ventilation system for the fire-fighting lobbies on the levels above ground resulted in reduced shaft sizes.

CASE STUDY: ME London hotel, Aldwych, London

Fire engineer Buro Happold

Architect Foster & Partners

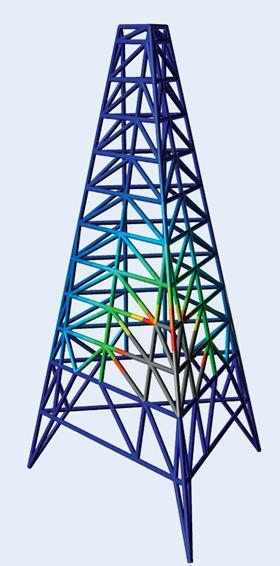

This hotel and residential refurbishment for Meliá Hotels International includes a 10-storey steel structure, the upper eight storeys of which form an atrium with a triangular plan.

Buro Happold was able to reduce the amount of fire protection without compromising the robustness and safety of the building by using a combination of tools: first, an analytical model that described the heat transfer from a fire at the atrium base to the steelwork; second, a numerical model of the atrium structure to calculate the response of the structure during a fire.

This process allowed the engineer to identify which steel members would need fire protection and how much would be required. The result was that all structural members below the base of the atrium required fire protection to an 120-minute standard dropping to 60 minutes for all members up to one level above the base of the atrium. From there to the roof level, only the three corner columns required 60 minutes fire protection.

Steelwork requiring protection is coated with an intumescent paint, which can be applied offsite to make site work easier.

CASE STUDY: 40 Springardens, Manchester

Fire engineer Arup

Architect Aedas

40 Springardens is a nine-storey, steel-framed office building, which includes a central atrium and two levels of basement parking. It is close to other buildings and is protected by sprinklers.

The structural fire resistance requirement in Approved Document B was 120 minutes. However, time equivalence analysis demonstrated that 60 minutes was sufficient to ensure that the structure would retain its stability in the event of a fire.

Smoke control provisions in the atrium were installed after an engineering assessment defined an appropriate amount of ventilation, and allowed the use of toughened glazing to enclose the atrium instead of fire-rated glazing.

In addition, an assessment of the potential for fire spreading externally eliminated the need for fire-rated construction for the external facade.

Prescriptive code recommendations would have required two fire-fighting shafts in the building. A single fire-fighting shaft was justified on the basis that coverage to all parts of the floor plate could be achieved within 60m from the dry riser in a single fire-fighting shaft. By providing a single shaft, the other stair core in the building did not require additional space for lobby ventilation or openable vents to the stairs. This reduced the area of the stair enclosure.

The smoke shaft size was reduced from 3sq m to 0.6sq m using a mechanical smoke shaft system designed on the basis of a clear layer smoke management system. This solution provided increased lettable floor area and a performance in excess of the guidance documents.

Postscript

For more information www.asfp.org.uk

In association with The British Constructional Steelwork Association and Tata Steel

No comments yet