Sponsored by Tobermore, this module explores permeable paving as part of a sustainable drainage system solution for housing developments, highlighting the benefits and challenges, alongside best practice guidance for design, construction and maintenance

As urban development accelerates and rainfall intensifies, traditional drainage systems are under unprecedented strain. The result? Rising flood risks, environmental degradation and a need to rethink how we manage surface water.

Hard landscaping plays an important role in mitigating these challenges, offering innovative solutions that combine functionality with sustainability. One approach is permeable paving, a versatile system that addresses drainage, enhances water quality and integrates seamlessly into sustainable drainage systems (SuDS). This module explores how permeable paving, alongside other hard landscaping strategies, can contribute to the creation of climate-resilient, sustainable housing developments.

Learning objectives:

- Understand the principles, benefits and challenges of permeable paving systems within SuDS.

- Identify best practices for specifying and constructing permeable paving to achieve safe and sustainable designs.

- Gain awareness of UK legislation, certifications and regulations shaping the adoption of SuDS, with a focus on permeable paving solutions.

- Recognise the critical design and maintenance considerations for sustainable hard landscaping in housing developments.

Flooding costs the UK approximately £340m annually, with sewer overflows contributing significantly to sea pollution in areas like the North-west of England – at a time when 15% of species are facing extinction due to habitat loss and environmental degradation. Addressing these interconnected issues demands an integrated approach to urban planning that prioritises biodiversity and climate resilience.

Solving today’s housing crisis is about more than building homes – it requires the creation of sustainable, mixed-tenure communities capable of supporting households for centuries to come. Hard landscaping is a crucial component of this vision, offering opportunities to integrate sustainable materials, improve drainage and water quality, and enhance biodiversity in residential streetscapes.

Paving solutions

Effective design for housing developments begins with pre-planning and infrastructure considerations. Levels, drainage and material selection are pivotal aspects of site layout, and each project has unique requirements.

Common paving materials include concrete, natural stone, asphalt, brick, porcelain and permeable paving. When selecting materials, key considerations include:

- Traffic volume: high-traffic areas require robust, durable materials.

- Aesthetic compatibility: materials should align with the overall design vision.

- Drainage: in areas prone to flooding, permeable options are critical.

- Maintenance: consider ease of upkeep and long-term durability.

- Budget: materials vary significantly in cost, impacting project affordability.

Introducing permeable paving

Permeable paving is one effective solution to the growing challenges of urban flooding and water management. It helps mitigate water runoff and integrates seamlessly into broader SuDS strategies.

The material enables water to infiltrate the ground, reducing surface runoff and supporting sustainable drainage. Composed of materials with built-in voids, such as concrete blocks, gravel or plastic grids, it allows water to pass through the surface and be stored in a reservoir beneath.

This water is then gradually absorbed into the soil or channelled through subsurface systems rather than overwhelming traditional drainage systems. Key benefits include:

- Runoff reduction: prevents water pooling and minimises strain on drainage systems.

- Pollutant filtration: filters contaminants before they reach waterways.

- Tree growth: supports urban forestry by improving soil hydration.

- Reduced salt use: limits the need for de-icing salt in winter.

Integrating permeable paving within SuDS frameworks

In most projects, permeable paving would be one element of a larger, more comprehensive approach to water management – SuDS. By mimicking natural processes, SuDS retain water on site and integrate features like infiltration basins, ponds and permeable paving to mitigate flood risks and improve water quality.

Principles of SuDS include:

- Attenuation: storing runoff and releasing it gradually.

- Infiltration: allowing water to soak into the ground.

- Harvesting: using rainwater near where it falls.

- Conveyance: transporting water on the surface, reducing reliance on pipes.

- Filtration: removing pollutants and sediments.

In the UK, the implementation of SuDS is underpinned by key legislation aimed at managing flood risks and promoting sustainable development:

- The Flood and Water Management Act 2010 provides a framework for flood risk management, encouraging the integration of SuDS into major developments.

- The National Planning Policy Framework (NPPF) mandates that SuDS must be considered for major developments, unless deemed inappropriate.

SuDS legislation in Wales goes a step further, requiring the incorporation of SuDS features into nearly all new developments, accelerating the adoption of permeable paving and other sustainable drainage solutions.

SuDS devices and the treatment train

With urban development and increasing rainfall showing no signs of slowing down, exploring alternative methods for managing surface water effectively is crucial. SuDS employ a variety of devices to handle runoff and improve water quality. Each device serves a unique purpose, offering distinct benefits in the treatment train (a sequence of processes used to manage and treat surface water).

Common SuDS devices include:

- Soakaways: excavated pits filled with aggregate to encourage infiltration.

- Filter strips: vegetated strips of land that slow runoff and filter pollutants.

- Swales: ditches that transport water while enhancing biodiversity.

- Bioretention areas: shallow landscaped zones for water filtration and retention.

- Infiltration basins: vegetated depressions that temporarily store water.

- Detention basins: basins that control runoff and allow sediment settlement.

While each SuDS device has pros and cons, the key to successful water management often lies in integrating multiple techniques, and some may be more suitable than others. Permeable paving is a versatile solution that fits seamlessly into the SuDS treatment train, using multiple devices in a sequence to manage water locally and reduce the burden on central drainage systems.

The treatment train and sub-catchments

The concept of the treatment train divides the area to be drained into sub-catchments – smaller sections with varying drainage characteristics and land uses. Each sub-catchment has its own drainage strategy tailored to its specific needs. This local management approach reduces the volume of water that needs to be handled at any single point and minimises the need to convey water offsite, preserving natural water flow patterns.

It is essential to consider how the division into smaller sections impacts the overall catchment management and hydrological cycle. By maintaining this broader perspective, we can ensure that the entire system works harmoniously to manage water effectively.

Pollutant removal

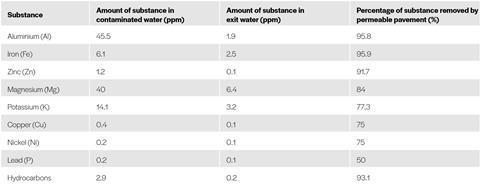

Significant research has demonstrated the impressive pollutant removal capabilities of permeable paving. It is widely recognised as an effective method for filtering out contaminants from surface water before it enters natural water systems.

A study by the Department for the Environment, Food and Rural Affairs’ pollution prevention department involved introducing 1,500 gallons of polluted water into a permeable paving system. After one hour, the system had removed over 90% of hydrocarbons and heavy metal pollutants. This effectiveness stems from how pollutants are trapped in the underlying stone layers, where natural micro-organisms break them down. Heavy metals that cannot be broken down adhere to the aggregate and remain securely trapped.

This cleansing process is far more efficient than oil separators, so permeable paving systems eliminate the need for petrol interceptors.

Some designs specify an upper geotextile layer between the bedding layer and aggregate in permeable paving systems, but British Standards regards this as optional, and studies have shown that it does not significantly improve water quality.

Inclusive environments

An essential consideration in any hard landscaping project, including the installation of permeable paving and other SuDS elements, is ensuring the design is inclusive and accessible. When designing outdoor spaces, it is vital to consider the needs of all users.

Poor design choices can create unnecessary barriers. For example, shiny or highly polished paving can appear wet, creating a slip hazard. High-contrast paving patterns may give the impression of uneven surfaces, which can be confusing or hazardous for people with limited sight or dementia. Additionally, sudden changes in paving patterns can disrupt people with mobility issues, while significant tonal changes in colour might be mistaken for patch repairs, particularly in asphalt. Mixed grey colours, although trendy, can make it difficult for people to spot functional elements such as bicycle racks or benches.

While more intricate designs and striking patterns can certainly be incorporated, simple, plain designs or blended tones are often the most effective in creating inclusive, safe spaces. These considerations should be integrated during the early stages of the design process, ensuring that the end result is accessible to all users, regardless of their specific needs.

Concept

Incorporating SuDS at the concept stage of a development is crucial for ensuring their effective integration. When considered early, SuDS are easier to incorporate into the site layout, allowing for more permeable areas and achieving the prevention phase of the management train. This proactive approach significantly reduces long-term challenges and enhances water management from the start.

At this stage, it is important to refer to the local flood risk management strategy and other relevant documents, such as local SuDS guidance. These will help inform the design and ensure alignment with regional policies and standards.

Early engagement with stakeholders – including local authorities, planners and environmental consultants – encourages collaboration and ensures that SuDS solutions are integrated into multifunctional spaces such as car parks, footpaths, gardens, landscaped areas, driveways, courtyards and communal spaces.

This holistic approach optimises cost-effectiveness and contributes to creating better environments that improve the quality of life for residents and workers alike. The integration of SuDS during the concept phase encourages the development of spaces that serve multiple purposes, making the built environment more sustainable and resilient.

Developed design

Once the concept stage is complete, the focus shifts to the developed design phase. Here, technical details and calculations come into play, particularly for systems like permeable paving. Ensuring the correct sub-base build-up is essential to support an effective permeable paving system.

Types of permeable paving systems:

- Type A (infiltration system): this option is suitable when the sub-grade has been tested and shows sufficient permeability. Water falls on the surface and drains through the joints in the paving blocks, filtering through the grit laying course and into a graded aggregate sub-base. The water then infiltrates directly into the ground via a permeable geotextile. This simple and typically economical solution does not require drainage pipes or gullies.

- Type B (partial infiltration system): specified when the sub-grade can absorb some water but not fully. This system is a hybrid between type A and type C, suitable for situations where the sub-grade’s stability is not compromised by some water infiltration. Outlet pipes in the sub-base manage excess water by directing it away from the system.

- Type C (attenuation system): used when the sub-grade is impermeable or if introducing water would destabilise it. This system captures all the water through an impermeable membrane placed on top of the sub-grade and forms a storage tank. The water is then directed to secondary drainage systems through outlet pipes. This solution prevents high water tables from rising into the sub-base, ensuring the system functions optimally. The outflow pipe diameter should be site-specific and determined by the project engineer.

Loading

Once the correct system type is determined, the next step is assessing the loading category. According to the British Standard for designing permeable pavements (BS7533:13), there are six loading categories based on the expected traffic. These categories are measured in terms of heavy goods vehicle (HGV) movements per week or millions of standard axles (one standard axle is 8,000kg).

If the loading category falls between two levels or is uncertain, always account for the higher level of traffic to ensure the design can handle the worst-case scenario. Once the appropriate system and loading category are selected, standard details for construction should be sought. These are often available in PDF and CAD formats, making them easy to share and integrate into the broader project design.

Technical design stage

At the technical design stage, civil engineering consultants typically provide site-specific preliminary designs. These preliminary designs outline the construction methods and are often sufficient for planning applications. However, if the project requires a more detailed and indemnified design for construction, consultants can provide these additional services. A thorough technical design ensures that the system is not only functional but also built to the correct specifications, reducing construction risks and improving the SuDS solution’s long-term performance.

Construction best practice

During the construction phase of permeable paving systems, attention to detail is critical to ensure long-term functionality and structural integrity. Proper material selection, installation techniques and attention to utility transitions are essential for achieving a successful build.

BS 7533:13 specifies the required aggregates for permeable paving:

- Laying course and jointing grit: 2mm-6.3mm clean grit. Sharp sand or kiln-dried sand must not be used, as these can wash away or solidify over time, becoming impermeable and causing joint and sub-base clogging.

- Sub-base: 4mm-20mm coarse graded aggregate. Type 1 MOT should not be used, as its finer particles may lead to blockages.

The sub-base must be compacted with a tandem roller or plate vibrator before screeding the bedding layer over the compacted aggregate. After block placement, the paving should be plate-vibrated, and the joints filled with grit to the top.

A few weeks after construction, any settled grit should be topped up. Approximately 1 tonne of grit is required for every 100m² of 80mm paving. Care should be taken to prevent soil contamination during construction, particularly near soft landscaping works.

Refer to BS 7533 Part 3 for additional installation guidance.

Common challenges and practical solutions

Sloped sites

Permeable paving can be viable on sloped sites. However, it is not recommended for gradients exceeding 1:20. Solutions such as lateral restraints, deeper sub-base areas or check dams (concrete baffles) can help slow water flow and prevent ponding at the base of slopes. Specialist advice is recommended for designing these systems, as discharge rates may also need consideration.

Downpipe integration

Roof drainage can be channelled directly into the sub-base, often with inspection chambers and catch pits as needed. This is compatible with both infiltration and attenuation systems, funnelling additional water efficiently into the sub-base.

Service corridors

Correctly designed service corridors are essential to avoid system failures. Historically, local authorities encountered issues when placing permeable systems above utility services. Water-sensitive assets may not tolerate permeable surfaces, and maintenance involving sub-base disturbance can lead to system failure. Keeping permeable systems separate from services ensures both stability and accessibility.

Installation and maintenance

Proper installation and maintenance are critical for long-term success and safety. Poor practices can lead to system failure and trip hazards.

- Joint filling: all joints must be filled with 2mm-6.3mm grit to the top to prevent block movement. After a few weeks, top up any settled joints. Approximately 1 tonne of grit is required per 100m².

- Compliance: installation should follow BS 7533 Part 3, which covers permeable pavements using clay, natural stone or concrete pavers.

Most manufacturers provide site-specific maintenance guides, which should be followed when using their designs. The following general maintenance recommendations are based on industry guidelines:

- Routine visual inspection once a year or following heavy rainfall

- Remedial maintenance for ponding as needed (brush/vacuum joints and replace grit)

- Structural maintenance (replace damaged blocks, repair rutting)

- Aesthetic upkeep (light pressure wash)

- Joint maintenance (brush/vacuum joints and replace lost material annually)

- Weed control (as needed with weedkiller)

- Winter maintenance (de-icing salts).

Sweeping twice a year is recommended to prevent clogging but requires no more effort than traditional pavements. Research indicates that whole-life costs of permeable paving are comparable to or lower than conventional materials with piped drainage.

Adoption

Governmental planning guidance across the UK mandates the use of SuDS wherever possible. Early liaison with local authorities ensures that permeable paving solutions meet their adoption criteria, which vary significantly between councils.

Permeable paving is typically designed to accommodate up to a 1:100-year rainfall event, surpassing conventional drainage systems such as gullies, which lose efficiency as sediment levels rise. Even with 90% clogging, permeable paving systems remain effective in handling UK rainfall events.

When specifying products, consider slip, skid and abrasion testing results. For instance, a polished granite surface may not be suitable for an educational facility entrance. The design process should involve collaboration between architects and engineers to ensure that aesthetic and functional requirements are met, as well as selecting the appropriate loading category, sub-base build-up and maintenance programme.

Rainey Endowed School

In 2009, Hydropave 240 permeable paving by Tobermore was selected for a resurfacing project at Rainey Endowed School in Magherafelt, Northern Ireland. The project transformed an existing car park into a multi-functional space incorporating parking and a playground. The school, situated in the Magherafelt basin with three roads descending toward it, had long grappled with challenging drainage issues.

To address these problems, a permeable paving solution was designed by SuDS expert Professor John Knapton. The system aimed to alleviate surface water runoff and manage drainage more sustainably, with mechanical installation carried out by Gibson Contracts.

Beyond its practical application, the project became a living laboratory for environmental science experiments. Encouraged by Knapton, two students, Ross Campbell and Joshua Smith, conducted research to demonstrate the environmental benefits of permeable paving and SuDS principles. With approval from the Department of the Environment’s Pollution Prevention team, Magherafelt Council introduced 1,500 gallons of polluted water onto the paved playground to begin the experiment.

To capture accurate data on the filtration performance of the Hydropave system, monitoring equipment was installed, including data loggers, flow meters, and temperature gauges. Water samples were collected throughout the system to test for pollutants. The results were impressive, with the paving system effectively filtering out numerous substances: the complete table of substances removed can be seen below.

In October 2009, the findings were presented as a technical paper at the 9th International Conference on Concrete Block Paving in Buenos Aires. The report was well-received by the international community. Knapton noted: “The experiments were sensational and will have a significant impact on how roads will be built in the future.”

Final thoughts

Permeable paving offers an attractive, durable solution with superior drainage capabilities. Proper installation, thoughtful design and minimal but effective maintenance can ensure these systems function well over time, contributing to sustainable urban development and resilient hard landscaping solutions.

To find out more about hard landscaping specification for housing developments, you can contact Tobermore directly.

Please fill out the form below to complete the module and receive your certificate.

No comments yet