The insulation of buildings has long been a concern, and the technology has continually evolved. This article focuses on a new insulation technology: vacuum-insulated panels. This module is sponsored by Kingspan Insulation.

West & Machell specified Kingspan’s Optim-R vacuum-insulated panels for student accommodation at Leeds University.

How to take this module

To take this module read the technical article below and click through to a multiple-choice questionnaire, once taken you will receive your results and if you successfully pass you will be issued automatically with a certificate to print for your records.

Building Regulations are becoming ever stricter on the energy efficiency of buildings. In the near future, meeting these higher standards will require thicker versions of currently available materials, and buildings will need to be designed to accommodate them. This, in turn, could eat into the living space that homes can provide for their occupiers or the saleable space for commercial properties.

The effectiveness of an insulating material is called the lambda value, measured in W/m-K. The lower the lambda value, the lower its thermal conductivity and the better its insulating properties.

Heat transfer through a volume occurs by three modes: convection, conduction and radiation. The most basic insulators rely on the principle of blocking the convection of heat.

This is achieved by creating a matrix of fibres or bubbles, as in mineral fibre or polystyrene (EPS). The voids in this matrix are then filled with a buffer zone of “still” air. Therefore a product’s insulation capacity is limited by the conductivity of air, which has a lambda value of 0.025W/m-K.

Added to the conductivity of the matrix itself, this produces typical lambda values of 0.03W/m-K or higher.

Aerogels operate on the same principle. By restricting the movement of air molecules in very small spaces, their insulation performance has been recorded to be as low as 0.012 W/m-K.

Replacing the air with a less conductive substance improves the insulating performance still further. Systems such as closed-cell PIR or closed-cell phenolic replace the air with a different gas, or blowing agent. The thermal conductivity of the blowing agent is significantly lower than air and therefore the overall performance is improved, obtaining minimum lambda values of about 0.02W/m-K.

However, using gas still adds unnecessary conductivity. In recent years, performance improvements in these products have been restricted to incremental steps, limited by the physical properties of the gases used.

Panel Development

Significant further improvement requires that the gas be removed altogether. A vacuum — a space that has been evacuated of air — has no thermal conductivity, and only radiation can pass through it. This is the principle used in the vacuum flask, invented by Sir James Dewar in 1892.

Vacuum-insulated panels (VIPs) themselves are not a new technology. The first rubber-enclosed panel was patented in 1930, while the first patent on a nanostructured VIP was filed in 1963. In 1999, the US Department of Housing and Urban Development evaluated the market potential for VIPs in residential buildings, evaluating 27 different constructions. In 2005, VIPs were used in the facade of a seven-storey mixed-use building in Munich, designed by architect Martin Pool. It was the first privately financed building to be entirely insulated with VIPs, and the first time the technology had been used in a building more than two storeys high.

Kingspan’s Optim-R VIP solution was launched in March 2012. Today’s VIPs are rigid boards with a microporous core made of three components: fumed silica, silicon carbide and fibre. This core is evacuated of air, encased and sealed in a thin, gas-tight envelope.

Advantages of VIPs

The key advantage of VIPs is their low thermal conductivity: declared lambda values of 0.007W/m-K can be achieved. This is three times better than existing high-performing materials and up to five times better than first-generation insulation materials.

The other principal benefit of VIPs is their thinness compared with other kinds of insulation panel. The panels specified for the Munich building, for example, were 20mm thick and covered with expanded polyurethane, while, externally, a render was applied. The total thickness of the facade was just under 120mm. By halving the thickness of the insulation, the useable floor area within the building was increased by 50sq m. Kingspan’s Optim-R VIP comes in thicknesses of between 20mm and 60mm. The company has compared its insulating properties with other commonly available insulation products and discovered that 200mm of a typical glass mineral fibre is equivalent to just 40mm of Optim-R, to achieve the same performance.

The thinness of VIPs offers obvious advantages in an era in which ever-tougher insulation requirements mean that greater thicknesses of insulation are needed, and living and working spaces could become proportionately smaller as a result.

There are additional benefits for refurbishment projects, where retrofitting improved insulation can lead to unforeseen costs if it is thicker than the building was designed to take. Extra measures are often needed to accommodate thicker walls, floors or roof — for example, the extension of eaves.

Multiple uses of VIPs

The high thermal efficiency and minimal thickness of VIPs may be an advantage in a number of other applications where space or structural depth is an issue. It should be remembered that, regardless of the application, VIPs should not be cut or penetrated because this would remove the thermal advantage of the vacuum.

Flat roofs

VIPs can also be used in flat roof constructions such as:

- a concrete deck roof with no ceiling

- a metal deck roof with no ceiling

- a dense concrete deck with a suspended ceiling and a green roof covering.

Again, they offer improved floor-to-ceiling heights and are ideal in situations where there are planning restrictions on building height, or where a sleek design is required.

VIPs must be installed over a separate vapour control layer, and are suitable for use with most fully adhered single-ply waterproofing membranes and some cold liquid applied waterproofing systems.

A VIP used on a dense concrete deck with a suspended ceiling needs to be only 85mm thick to meet the target U-value for new homes, compared with 180mm for a PIR equivalent. To achieve a U-value of 0.18W/m2K — the Building Regulations target for a refurbished roof — the VIP saves 30mm compared with PIR.

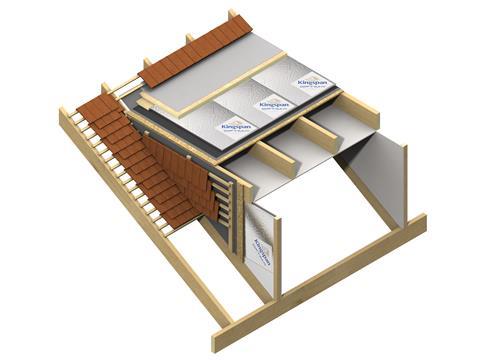

Dormers

VIPs can be used on dormer windows, both on the roof and on the cheeks. This provides more space inside the dormer and can improve the appearance of refurbishments, as external insulation will be closer to the original roofline, which can also aid compliance with local planning conditions.

If VIPs are applied on the outside of the cheek, ventilated cladding is required in the form of timber cladding, render, render on carrier board, slates, tiles or a tiling batten.

Roof systems are best used in conjunction with a protection layer, vapour control layer and waterproofing layer.

External wall insulation

VIP systems can be used in a number of external wall applications, including:

- on solid and cavity brick walls

- on solid blockwork

- behind timber cladding, slate or tiles, brick slips and render

- incorporated into rainscreen cladding systems.

For new-builds, VIP external insulation is particularly useful on tight sites or where extra interior space is needed. On both new-builds and refurbishments, thinner insulation maximises the amount of daylight entering the building. Some panels, such as Kingspan’s Optim-R Flex, are designed to be cut to fit around penetrations, brackets, reveals and where fixtures and fittings need to be installed.

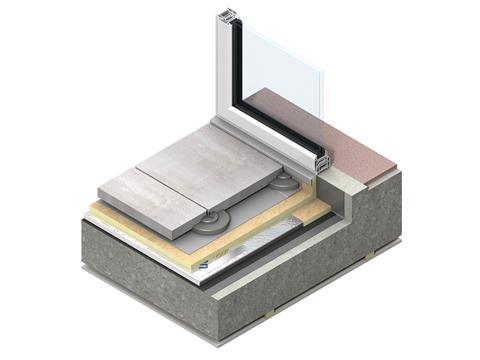

Balconies and terraces

VIPs are particularly useful for maintaining an even transition between indoor and outdoor levels. They can be installed on a dense concrete deck with suspended ceiling or a timber deck with plasterboard ceiling. There are also systems that are suitable for use under most warm green-roof terrace systems. The total required dry weight will depend upon wind uplift, which in turn will vary with the geographical location of the building, local topography, and the height and the width of the roof itself.

VIPs are suitable for use with most fully adhered single-ply waterproofing membranes, cold liquid applied waterproofing systems and most fleece-backed single-ply waterproofing membranes.

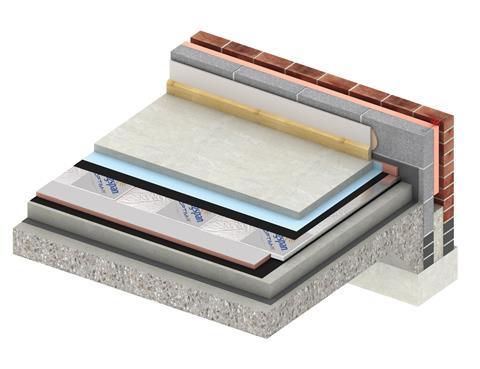

Flooring

VIPs can be used on solid concrete-based floors, as well as beam and dense block ground floors. In addition to improving U-values, the use of VIPs can maximise floor-to-ceiling heights.

In refurbishments, the use of thicker insulation often means that ground-floor door lintels, radiators and skirting boards all need to be raised. The alternatives, such as excavating more deeply or installing a replacement concrete floor, are usually more costly and time-consuming.

Again, using the two Kingspan products as comparisons, in order to achieve a U-value of 0.13W/m2K — the best starting point for new homes under Building Regulations — the VIP needs to be just 40mm thick (at a perimeter/area ratio of 0.3), while the EPS board must be 190mm.

To achieve a U-value of 0.25W/m2K — the Building Regulations requirement for the refurbished elements of existing buildings — the VIP can be just 20mm thick, compared with 70mm for an EPS board.

BD’s free continuing professional development distance learning programme is open to everyone who wants to develop and improve their professional knowledge.

These modules can contribute to your annual CPD activity and help you maintain membership of professional institutions and bodies.

This module will contribute 1 hour towards your CPD obligations. If successfully completed, certificates will be distributed two weeks after the module closes.

Duration: 1 hour

Module 19 Deadline: October 25 2013

Postscript

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. “UBM Information Ltd” may send updates about BD CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by “UBM Information Ltd” or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, please write to the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com.

3 Readers' comments