All the roofs at St Catherine’s College were recently condemned thanks to the presence of RAAC. Thomas Lane reports on how the team came up with a solution that didn’t affect the historical significance of the Arne Jacobsen-designed campus

The master, fellows and students of St Catherine’s College are among the lucky few to occupy that special and rare commodity, a postwar grade I listed building. Or rather they were until the end of last year when they were forced to move into marquees thanks to the discovery that the roofs of virtually the entire college were constructed from problem material reinforced autoclaved aerated concrete (RAAC) and were at risk of collapse.

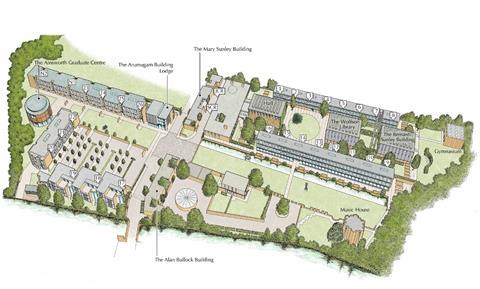

The college is one of Oxford University’s newest, dating from 1962. It was designed by celebrated Danish architect Arne Jacobsen and is thought to be one of the best preserved and most significant examples of his work. The college is formed from a collection of long, low modernist buildings arranged around a traditional college quadrangle. Internally, these are distinguished by deep, strongly expressed precast beams which create generous, column-free spaces. Many of the buildings feature ribbon rooflights arranged over these beams which serve to get light deep into the plan and emphasises the structure.

The Jacobsen campus includes the kitchen, a spectacular dining room, the junior and senior common rooms, library and the Bernard Sunley building which houses a lecture theatre and meeting rooms. There are also two student accommodation blocks. The roofs of all these buildings feature RAAC planks fitted between the precast beams and add up to 8,074m², bigger than a professional, full-sized football pitch.

The roofs were inspected by structural engineer AKS Ward after the high-profile school RAAC roof collapses last summer. The engineer discovered that the RAAC planks were in very poor condition with water staining, sagging, cracking and damage thanks to changes to the services over time. It also found the precast beams were 150mm wide with rebar loops down the centre to create a grouting line. Consequentially, the bearing area of the beams was less than 75mm and deemed to be a critical risk according to Institution of Structural Engineers guidance. The whole lot was condemned, leaving the college with no other choice than to vacate the buildings. The accommodation blocks remained open with students now sharing their bedrooms with props supporting the ceilings.

The college needed a rapid solution to the problem as the temporary accommodation was costing it a fortune. It has also lost income from summer conferences and is deeply unsatisfactory for staff and students.

“The loss of space and loss of revenue has really driven the project,” explains Matthew Tromans, partner at Oxford Architects which was engaged to help fix the problem. “The college want to get their spaces back as quickly as possible. They’ve accepted that they will lose this summer’s conference trade but would really like to not lose next summer’s.”

Oxford Architects, along with the rest of the team, was engaged by the college at the end of 2023. Remarkably, the team have carried out research into the building construction, explored a wide range of options and come up with a solution in just six months with Oxford City Council granting permission at the end of July.

A key driver, other than the pressure to move quickly, was devising a solution that didn’t damage the heritage value of the buildings. In other words it needed to be invisible. How have the team risen to this challenge?

Troman says close collaboration with AKS Ward, Historic England, the council and the Twentieth Century Society was key to achieving the fast turnaround.

A major constraint was the fact the college buildings are spread over a wide area. Tromans says three tower cranes would have been needed to reach all the buildings.

“All we could say with any certainty was that the existing structure was capable of carrying the existing load”

Matthew Tromans, partner at Oxford Architects

Access was very limited, which meant getting the cranes to and from site would have been a challenge plus there were limitations on the size of the components which could be brought in.

A two-stage procurement route was deemed to be the best approach as this meant a contractor could be brought on board early to ensure the solution was deliverable. Beard was appointed under a pre-construction services agreement.

>>See also: Does the latest RAAC research mean remediation could be easier and cheaper than all the panic suggests?

The light weight of the RAAC planks meant the original engineer, Arup, could minimise the size of the beams, columns and foundations. The original drawings were still available but as built ones could not be found.

“All we could say with any certainty was that the existing structure was capable of carrying the existing load,” Tromans explains. “AKS Ward was very nervous about imposing any additional load onto a relatively unknown structure, especially one that’s as significant and irreplaceable as St Catherines. Retaining or not exceeding the existing load became a pretty key constraint with any new design.”

One option was to retain the RAAC planks by supporting these with new structure below. As new columns would be needed to support the additional weight this was quickly ruled out on the grounds this would have an unacceptable visual impact on the large open spaces. It was agreed that the RAAC planks would need to be removed and replaced by a new roof deck.

The team considered concrete, timber and steel decks. An options matrix was created to consider weight, ease of installation and deck thickness as this affects the external appearance of the buildings. The matrix also considered the bearing area on the precast beams and compatibility with the rooflights and other roof level elements.

Concrete deck options were ruled out thanks to its weight. The light weight of timber made it a promising alternative and options including traditional timber joists with a plywood deck were considered, and ruled out on the grounds this was too labour intensive. SIPS and CLT panels had the advantage of being quick to install but needed tower cranes for installation. Ultimately timber was dismissed because the college’s insurers preferred a non-combustible solution.

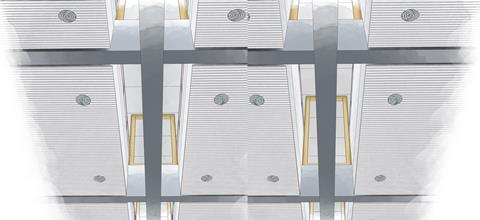

This left steel. A lightweight SFS steel framing solution utilising C section beams clad with profile metal decking was selected as this is lightweight and easy to install without the need for a crane. “It is lightweight, non-combustible and dimensionally stable,” Tromans says. “The SFS and deck are part of a single package which the main contractor liked.”

At 150mm deep, the deck will be the same as the thickest, existing RAAC planks. But the roof build up will go deeper as the college, which will be spending some £30m to fix the RAAC problem, wanted to leverage some extra value from its money. “If we had returned them a roof that performed no better than their old roof and they’ve gone through a year and a half of disruption and a huge capital spend, that would be pretty difficult to swallow,” Tromans says. The plan is to insulate the roof to cut energy use and help the college meet its net zero aspirations.

PIR insulation was selected as this offers the best performance for the thickness and can be specified as tapered boards, necessary to increase the inadequate fall of the existing roof. This means the thickness varies but should make a meaningful difference to the thermal properties of the roof. But this was going to increase the roof height.

Tromans says the roof height has increased over time. “All of the roofs have been messed around with over time and had new felt roofing and new roof trims applied,” he says. Originally the top of the roof was 330mm above the eaves but accretions over the year had pushed this up to 370mm in places. The insulation increases the height up to 420mm, approximately 100mm higher than when the building was completed.

Tromans says: “This was discussed at length with Historic England and the other consultees, and all agreed that that [adding insulation] should be the aspiration, but if this was resulting in roof build ups that were detrimental in Historic England’s eyes to the significance of the building then we would have to revisit that. I am pleased to say we managed to get it to a point where Historic England were satisfied that a reasonable balance has been met.”

A raised roofline had a consequential impact on the rooflights. These are arranged in rows over the beams and stand proud of the roof with vertical, ribbon glazing on either side.

If left unaltered, the increase in roof height would reduce the effective height of the rooflights, making them appear squat when seen from the ground and reducing the amount of light entering the building.

Raising the rooflights by adding a spacer was considered but discounted on the grounds this would be visually intrusive. The solution is to extend the height of the metal goalpost shaped rooflight frames by splicing in new metal.

A planning and listed building consent application was submitted to Oxford council at the beginning of June and has just been approved.

This covered all the non-residential buildings as the college wants to get these back in use as a priority. Preparing the application for the accommodation blocks at the same time would have taken another month or two so this was submitted seperately. Getting approval for this should be a formality given the similarity of the buildings and proposed solution.

Work will start as soon as possible now permission has been granted. A big part of the job will be preparing for the construction work. “The temporary works is a huge piece of work in its own right,” Tromans says. The buildings will need to be wrapped externally with scaffolding including a temporary roof to keep the weather out.

The RAAC needs to be propped from below while the roofs are stripped, necessitating a full internal birdcage scaffold complete with crash decks. This includes lining the interior with OSB and using purpose built boxes to protect the integrated furniture and panelling.

The combination of the scaffolding, which is three to four metres deep around the buildings, and the space taken up by the temporary facilities means access to the site will be very constrained.

The ambition is to complete the phase one work by next Easter in time for the summer conference season.

St Catherine’s isn’t alone with the nature of this challenge, the distinctive Ziggurats, the grade II* listed Denys Lasdun-designed student accommodation at the University of East Anglia are currently empty while solutions are discussed with Historic England and the local council. They could do worse than talk to the team at St Catherine’s.

>> Also read: Conference to mark 60th anniversary of Jacobsen’s St Catherine’s College

Project team

Client St Catherine’s College

Architect Oxford Architects

Project manager and cost consultant AtkinsRéalis

Consultant architect to the college Pendery Architecture & Heritage

Planning and heritage consultant Edgars

Landscape architect Colvin & Moggridge

Services engineer Ingleton Wood

Structural engineer AKS Ward

Contractor Beard Construction

No comments yet