As we look to expand the role of MMC to deliver buildings fit for a net zero future, we need to be aware that some very familiar supply chain risks can still exist

Modern methods of construction, or MMC, are at the heart of helping the built environment to play its part in tackling the climate emergency. Through initiatives like the Construction 2025 strategy, which was developed in partnership with the UK construction industry, the government is providing funding for new and innovative building solutions. It has also committed to more procurement of MMC.

MMC offers many well-publicised potential benefits over traditional procurement and build methods. However, in looking to expand the role of MMC to deliver buildings fit for a net zero future, we need to be aware that some very familiar supply chain risks can still exist. With that in mind, can we develop forms of MMC that can reduce those risks?

How does a construction platform approach differ from other types of MMC?

When we talk about ‘modern methods of construction’, are we always clear about exactly which method we’re referring to? There are a variety of ways of providing MMC, each with different benefits and challenges.

Volumetric and panelised MMC, for example, are very different to one another. To a degree, both rely on taking standard site practices and moving them into a factory environment, with subsequent finishing on site. This offers some time and cost savings, and reductions in waste, but it still means that the end product is bespoke to the manufacturer that produced it. There is little in the way of standardisation.

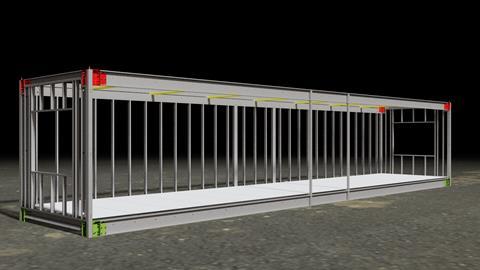

Construction ‘platforms’ are a different way to think about MMC. They are based around a ‘kit of parts’ approach, the usual analogy for which is the automotive industry. A construction platform solution offers great versatility, as it can be assembled on site, or used to create volumetric and panelised buildings.

What are the benefits of standardisation and interoperability in MMC?

A kit of parts is designed for manufacture and assembly, otherwise referred to as DfMA (it is also referred to as P-DfMA, with the ‘P’ simply representing a ‘platform’ approach to DfMA). It can be used for buildings and projects of all types. Crucially, it can feature a high level of standardisation.

Where standardisation doesn’t exist in MMC, a level of risk is always present. A lack of standardisation means different systems are incompatible, causing errors, delays and defects. By committing to one company’s solution, should that company fail for any reason mid-project, another company’s solution could not interact with it and be used to finish the project.

P-DfMA can offer that interoperability, improving the resilience of the supply chain and driving a much wider adoption of MMC.

Without that resilience, MMC - and P-DfMA specifically - are likely to remain a niche solution that the rest of the construction is wary of adopting. As a result, the industry is much less likely to meet its goals of improving the adaptability of buildings, and increasing the likelihood that components and building elements are reused.

Standardisation means that information is available, and everything about a system and its components is therefore known. That gives an understanding of how components can be reused, which means they have a value at the end of the building’s life. In future, this is likely to mean that a modular manufacturer would buy back a structural frame because they know it could be reused.

Demonstrating the capabilities of P-DfMA through the Seismic II project

Government funding aimed at making P-DfMA solutions a reality led to the creation of the consortium-led Seismic II project.

The Seismic consortium was made up of: construction consultants Blacc; the Manufacturing Technology Centre (MTC); two offsite manufacturers, Elliott Group and the McAvoy Group; Tata Steel; the Active Building Centre (ABC); and the National Composite Centre (NCC).

Seismic II has shown how standardised components can be mass-produced to deliver better quality, performance and value for sectors including education and healthcare. The project encompassed the production of wall, floor, ceiling and roof components that are all completely interoperable with a standardised light steel frame.

Buildings can be specified, safe in the knowledge that there are multiple options available for the repair, maintenance or replacement of components, and for the extension, adaptation and reuse of buildings. The supply chain will therefore be more willing to invest in and engage with P-DfMA solutions as we seek to move away from a reliance on traditional procurement and construction methods.

Alongside the Seismic II platform, Tata Steel is involved in multiple initiatives aimed at proving the concept of construction platforms and applying them across different sectors. To keep up to date on our activity in modular construction, sign up to our newsletter.

![Ashton Sixth Form College - EQUITONE [tectiva]](https://d3rcx32iafnn0o.cloudfront.net/Pictures/100x67/3/6/4/1996364_ashtonsixthformcollegeequitonetectiva_882316.jpg)