Rooflights can help to transform a roof into usable, desirable space. This module, sponsored by Glazing Vision, outlines how to design an attractive, safe rooflight in accordance with Part K of the Building Regulations

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 22 SEPTEMBER 2017

INTRODUCTION

Rooflights can provide a safe and secure means of accessing a roof and increasing usable space by converting flat areas into terraces and roof gardens. They can also be installed to provide less frequent access to a roof area for maintenance.

This CPD discusses how Approved Document K may affect the specification of rooflights and how good design can aid compliance with Building Regulations. Approved Documents are a series of guidance notes approved by the Secretary of State which provide practical guidance on meeting the technical requirements of the Building Regulations for England. Scotland, Wales and Northern Ireland are covered by separate regulations and therefore requirements may differ.

Approved Document K supports Part K of the Building Regulations, which concerns protection from falling, collision and impact. It was last updated in April 2013 to amalgamate Approved Document N on the safety of glazing in relation to impact, opening and cleaning, and additional guidance from Approved Document M which concerns access to and use of buildings.

ACCESS REQUIREMENTS

Requirement K1 ensures that stairs, ladders and ramps are appropriate to afford reasonable safety to people gaining access to and moving about buildings. It covers their design, construction and installation, including steepness, rise and going, handrails, headroom, length and width.

When providing access to a roof space, there are several factors that must be considered in order to comply with Building Regulations. The first is why roof access is required: if it is only for infrequent or maintenance access, requirements are different to where regular access is required. Once this is determined, Building Regulations dictate how the rooflight should be approached and the safety features that should be employed, both in the unit itself and on the roof surrounding the opening.

For maintenance access it may only be necessary to provide a temporary set of ladders and a latch-way system on the roof, because greater care can be expected from those required to gain access. Regular access to a terrace area, however, is likely to necessitate a full flight of stairs and a suitable balustrade around the opening. Public buildings will require a higher level of safety provision due to inhabitants’ relative unfamiliarity with the building and the increased number of users.

Where stairs or ladders are used for maintenance access at least once a month, designers should refer to the provisions for private stairs in dwellings or for industrial stairs and ladders in BS 5395-3:1985, “Stairs, ladders and walkways. Code of practice for the design of industrial type stairs, permanent ladders and walkways”, which is no longer current but still cited in Building Regulations.

If maintenance access is required less frequently, it may be more appropriate to use portable ladders covered by the Construction (Design and Management) Regulations 2007.

For regular or terrace access, measures will vary depending on the scheme but it is widely accepted that a permanently installed flight of stairs offers the most appropriate solution for those looking to access a roof terrace via a rooflight or any other means. It is strongly recommended that designers consult the local Building Control officer for advice.

MINIMUM HEAD HEIGHT

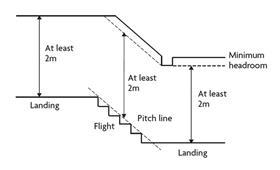

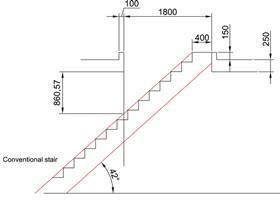

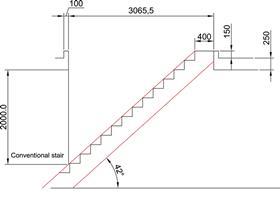

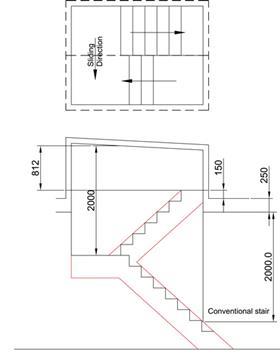

Approved Document K also provides guidance on minimum head heights, stating that a minimum headroom of 2m (measured from the pitch line) is adequate for access between levels (see figure 1). Assuming that the application is considered a “private stair”, intended for use in only one dwelling, the maximum permitted pitch would be 42°. Average roof thicknesses can be considerable when requirements for structural load and insulation are taken into account, so specifiers should take care that the void or opening created in the roof and the rooflight itself are physically large enough to achieve the required 2m at the maximum permitted pitch.

Figure 3 demonstrates that the minimal internal opening required to comply with Part K is 3065mm. This is the only compliant solution where the width of the rooflight is no greater than the width of the stair.

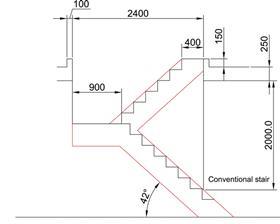

Where the width of the opening is wide enough to accommodate double the stair width, and a landing can therefore be incorporated, the minimum internal length of the rooflight reduces to 2.4m based on a 900mm landing (see figure 4 ). To comply with Part K, the landing must be at least the same as the

width of the stairs. The suggested minimum width of stairs in England is 800mm, although in some circumstances they can be as narrow as 600mm.

Product manufacturers can offer guidance on size limitations and materials specifications. For example,

glass rooflights can become more complex and difficult to open in larger sizes due to the sheer weight of the material. This will also have a bearing on cost.

Figure 5 shows that where the rooflight does not provide a completely clear opening, the headroom of the partially open rooflight frame should also be taken into account, as should the headroom of the internal ceiling. In this example, one half of the rooflight slides over the other, providing only a 50% opening. In this instance, a box rooflight would be more appropriate than a flat sliding rooflight because it provides additional headroom.

A box rooflight adds head height above the internal ceiling level, and if designed correctly, can provide the necessary clearance for access. Box rooflights tend to open by sliding sections of glass, rather than a hinge, so careful positioning of the stair, and therefore the threshold, is important. In most cases, box rooflights

are operated at a distance either by a wall-mounted control unit or remote control.

STAIRS AND LANDINGS

For permanent flights of stairs, Part K includes guidance on the minimum requirements for both the rise and going of steps.

For access rooflights, the final step should be considered to be a landing, in accordance with section 1.20. At the top of the flight of stairs, where the user is to exit on to the roof, there should be a minimum tread width of 400mm.

Where consecutive tapered treads are specified, the going will be the same on each. For a stair consisting of both straight and tapered treads, the going of the tapered tread should not be less than that of the straight tread. The going should be measured at the centre of the tread and a minimum width of 50mm should be provided at the narrow end. Installing a flight of stairs in a dwelling incorporating tapered treads is permissible and covered under “special stairs” in Approved Document K.

In some cases, there may simply not be enough space to accommodate a full flight of stairs. Section 1.29 covers the use of alternating tread stairs. These can save valuable space and work at a steeper pitch, but Part K recommends their use only for loft conversions, when there is not enough space for a full flight and the stairs provide access to only one habitable room. This is justified by the expectation of limited use, and that the number of people likely to be using the stair at any one time will also be limited. The number of people expected to access a roof terrace would normally be higher than for a single habitable room. This type of stair should be considered a last resort. Budgetary considerations are highly unlikely to be accepted by Building Control as justification.

Approved Document K does not cover roof terrace access specifically but advice from LABC states that an alternating treadstair is of limited use and would not satisfy the requirements of Part K under general circumstances. It is recommended that specifiers seek advice from the local Building Control officer if they are considering alternatives to a full flight of stairs.

Section K1 also covers the construction of steps, and states that the rise and going of each step should be consistent throughout the flight of stairs.

It goes on to state the benefits of installing steps with risers, noting that this removes the possibility of the front of a foot or walking aid being caught underneath a tread during ascent, potentially causing a fall.

Section 1.9 specifically refers to dwellings and states that steps may have open risers provided that the treads overlap by a minimum of 16mm, and that steps are constructed so that a 100mm-diameter sphere cannot pass through

the open risers.

In many cases, installing a flight of steps with open risers in conjunction with a rooflight can increase the amount of natural daylight available in the stairwell.

TERRACES, GUARDS AND BARRIERS

Section K3 on guards and barriers covers several instances where safety barriers may be required. With regard to rooflight installations, it refers specifically to pedestrian guarding where it is reasonably necessary for safety to guard the edges of any part of a roof including rooflights and other openings. In single-family dwellings and residential buildings, the minimum height requirement for such elements is 900mm on stairs, landings, ramps and edges of internal floors and 1100mm for external balconies and edges of the roof. This is particularly relevant when considering a roof terrace where the sole means of access is via an opening rooflight, because barriers may be required around the opening. Whether a barrier is ultimately required will depend on product selection and operation and orientation on the roof in relation to the building fabric.

Hinged access rooflights can be safely used with minimal barriers if the scheme and layout of the building permits and the orientation of the rooflight is considered carefully. The opening section of the rooflight can be used as a safety barrier while in the fully open position provided it meets the minimum criteria in Approved Document K with regard to sizes and that the glass is compliant with Approved Document N in relation to safety glass.

In the example shown in the photo, above, a hinged opening rooflight has been installed directly adjacent to a party wall so that when it is fully open the wall and the glass act as barriers along both lengths of the opening. All that is then required is a balustrade at the rear. Had the rooflight been installed in the opposite orientation, a barrier would have been necessary along the length. Box rooflights are the ideal solution for those wishing to avoid additional barriers or balustrades around the rooflight. Because they are constructed as a physical structure, the glazing of the rooflight itself forms a barrier.

The materials used, particularly the glass itself, must comply with Building Regulations. Reference should be made in this case to requirement K4: Protection against impact with glazing, which states that any glazing with which occupants are likely to come into contact while moving in or about the building should:

a) If broken on impact, break in a way which is unlikely to cause injury, or

b) Resist impact without breaking, or

c) Be shielded or protected from impact.

In order to meet this requirement, in critical locations one of the following approaches would be accepted:

a) Measures to limit the risk of cutting and piercing injuries by the use of glazing that is reasonably safe, such that, if breakage did occur, any particles would be relatively harmless

b) Use of glazing sufficiently robust to ensure that the risk of breakage is low

c) Steps are taken to limit the risk of contact with the glazing.

In the case of rooflights, the most common solution is to specify toughened safety glass

which is designed to fracture into smaller, less harmful pieces in the event of breakage. Some rooflight manufacturers offer higher specification heat soak tested toughened safety glass. This reduces the risk of nickel sulphide inclusions formed during the toughening process, which can lead to spontaneous glass fractures. Another option would be to specify glazing with a laminated interlayer designed to hold any fractured sections of glass intact.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 22 SEPTEMBER 2017

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about Building CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at www.building.co.uk/cpd

No comments yet