Building information modelling is now starting to make dramatic changes to the process of construction. In response, the role of manufacturers is evolving to ensure continuity throughout the life of the design. This CPD module is sponsored by Kalzip

How to take this module

To take this module read the technical article below and click through to a multiple-choice questionnaire, once taken you will receive your results and if you successfully pass you will be issued automatically with a certificate to print for your records.

Building information modelling is defined by the government’s Bim Working Party as: “a managed approach to the collection and exploitation of information across a project. At its heart is a computer-generated model containing all graphical and tabular information about the design, construction and operation of the asset.”

A building information model is intended to be an interactive single source of information for designers and constructors of buildings, and the facilities managers who will maintain them throughout their lives.

It will centralise many disparate sources of information, with sections, elevations, plans, renders, 3D walkthroughs, specifications, details and technical information and materials embedded in the model.

There is widespread agreement throughout the construction industry that building information modelling will dramatically change construction techniques. However, there is little definitive agreement on what exactly these changes will involve or how manufacturers of building components should respond. Manufacturers must therefore come up with solutions to enable the industry to move forwards, without a clear consensus on what the problems will be.

This module will discuss the challenges from a manufacturer’s point of view and some of the possible solutions, in an attempt to contribute to the debate on how the industry can progress.

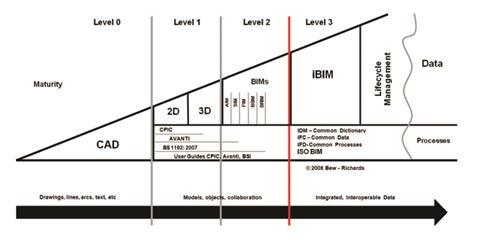

BIM maturity Model

In the Bim Working Party’s report, the levels of bim maturity are defined as:

Level 0

Unmanaged cad, probably 2D, with paper (or electronic paper) as the most likely data exchange mechanism.

Level 1

Managed cad in 2D or 3D format using BS1192: 2007, the British Standard concerning the management of construction information, with a collaboration tool providing a common data environment, possibly some standard data structures and formats. Commercial data managed by standalone finance and cost management packages with no integration.

Level 2

Managed 3D environment held in separate discipline bim tools with attached data. Commercial data managed by an enterprise resource planning (ERP) system. Integration on the basis of proprietary interfaces or bespoke middleware could be regarded as “pbim” (with

p standing for proprietary). The approach may use 4D programme data and 5D cost elements as well as feeding operational systems.

Level 3

Fully open process and data integration enabled by web services compliant with emerging IFC/IFD standards, managed by a collaborative model server. Could be regarded as “ibim” or integrated bim, potentially employing concurrent engineering processes.

Implementing BIM

Despite this uncertainty, there is nevertheless a sense of urgency in the adoption of bim, driven by government.

In March 2011, the Bim Working Party produced a strategy paper for the Government Construction Client Group, entitled Bim: Management for Value, Cost and Carbon Improvement, which set a target of 2016 for “fully collaborative” 3D bim, with all project and asset information, documentation and data in electronic form, to be used on all centrally procured government projects, irrespective of size.

The paper also included a bim maturity model (see box, left), to show the levels of competence required and remove ambiguity surrounding implementation, setting four levels from 0 to 3. All suppliers of construction services to the government must be able to deliver information and services to Level 2 of the model by 2016.

Meeting Level 2

Manufacturers must be able to provide data in a format that can be included in a project’s building information model to meet the government deadline.

Traditionally, manufacturers have provided architects with design advice and standard details, NBS specifications, drawings and information to meet regulations on the Control of Substances Hazardous to Health (COSHH). However, there has been no opportunity for this information to evolve with the project, often resulting in contradictory project documents.

Kalzip has been working on projects at Level 2 for more than four years, and is now working to include more information to work to Level 3 and beyond.

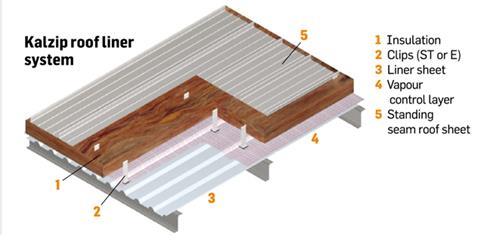

Kalzip has identified the most common “system families” of specifications which are most likely to be required in a format compatible with bim. The image below shows a simple roof construction with these areas highlighted.

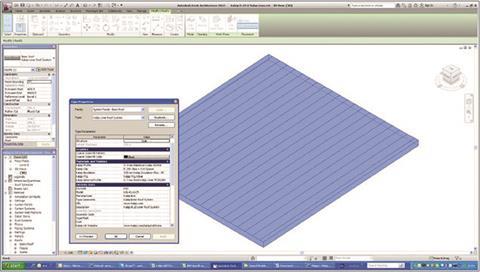

Kalzip has converted these system families of specifications into a series of standard constructions, in software formats including Revit and IFC, known as volumetric models. The Revit versions can be downloaded from www.kalzip. com, with other formats available on other external hosting sites.

A range of product information is embedded into these models, including:

- 2D system build-up

- Thermal performance

- Acoustic performance

- Structural performance

- Fire performance

- COSHH documents

- BBA

- Product literature

This reflects the most common queries received by our technical department — with acoustics, structural and hygrothermal subjects the most frequent.

These volumetric models indicate construction depth and can be inserted into master building information models, but they do not offer a great deal of detail. They should be suitable for standard projects, but more complex ones will require more specific input.

The volumetric models do not currently include information on programme, photographs or guarantees. They can be used for clash detection, but cannot confirm whether the supporting structure is suitable for the roof. If the steelwork or wind loads of the project are not included in the preliminary design, this must be rectified, often post-tender.

We recommend that designers contact manufacturers’ technical advisers — who will be able to advise on the correct model — at the specification stage. The integration of the roof with the supporting steelwork is critical. Early involvement of the manufacturer will ensure the model does not contain significant gaps.

In addition to providing standard models, the role of the manufacturer will evolve to become part of the design team to ensure feasibility and continuity throughout the project design — manufacturers understand the limitations of their products and of installers.

The earlier in the design process that the manufacturer is involved, the bigger the potential saving in time and cost. For example, on one complex sports project, manufacturer Kalzip worked with the architect on a redesign to reduce the number of complex sheets required without compromising the architectural intent, with both working off a single model.

Beyond Level 2

Kalzip’s design team is also able to provide a fully detailed roof element, in Revit or in other formats, to be included in a project building information model. This can then be used for clash detection, lighting studies and walk-throughs. With greater detail than available in the standard volumetric models, it ensures greater certainty for both the design and cost analysis.

Kalzip’s bim offer includes issuing a full, complete bespoke bim model for a project, once the project’s technical requirements have been established. Once the model is complete, the following can be obtained automatically:

- Architectural drawings, including plans, details and sections

- Cassette assembly drawings including plans, details and sections

- Bill of materials for procurement

- Component fabrication drawings

The model allows updates at architectural drawing level to cascade automatically through other drawing sets. Two-dimensional drawings can also be produced from the solid model, and as they are taken from the same central set of information and only one set of drawings is created, this should reduce contractors’ tender costs.

Installation methodology can be included, and in time Kalzip hopes to work with our supply chain to add a programme that the installation sequence. This may be added after the design stage when a contractor is appointed.

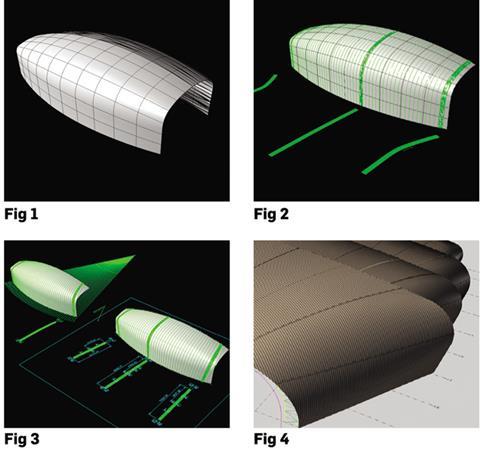

Case study: surface modelling

For South Bristol Skills Academy, Kalzip was able to provide the geometric design for its complex shape and produce drawings compatible with the central building information model using Rhino-based software.

Fig 1 Kalzip’s design team takes the steelwork or the architect’s 3D model and superimposes the cladding skin to assess which product would be required to replicate the geometry.

Fig 2 The shapes required of individual sheets are assessed and included in the model.

Fig 3 Kalzip also provided design advice on the preferred sheet orientation to fulfil the design intent in the most cost-effective way.

Fig 4 Once the layout is complete and agreed, it is provided to the design team for inclusion in the central model. Sheets are then manufactured in line with the model.

The manufacturer’s design is used on site to ensure that the structure and the halter clips are set out correctly, critical to the success of the project. Because neither lasers or string lines were available, the accuracy of the surface model is key.

How to take this module

To take this module read the technical article below and click through to a multiple-choice questionnaire, once taken you will receive your results and if you successfully pass you will be issued automatically with a certificate to print for your records.

MODULE 17 DEADLINE: December 21 2012

Postscript

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. “UBM Information Ltd” may send updates about BD CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by “UBM Information Ltd” or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, please write to the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com.

No comments yet