Finalist for Interior Architect of the Year Award 2024, HLM Architects guides us through the specification challenges present at the National Manufacturing Institute Scotland

HLM Architect’s body of work has been shortlisted for this year’s AYAs, as the practice was named a finalist for three awards, including Interior Architect of the Year.

In this series, we take a look at one of the team’s entry projects and ask the firm’s interior designer, Mhairi-Claire Wilkes, to break down some of the biggest specification challenges that needed to be overcome.

What were the key requirements of the client’s brief? How did you meet these both through design and specification?

The interior design brief for the National Manufacturing Institute Scotland (NMIS) focused on creating an open and collaborative environment that fosters the sharing of knowledge and creativity. The building aims to serve as a catalyst for future development, attracting world-leading companies and institutions at the forefront of advanced manufacturing.

The NMIS brief identified four principal elements:

- The Digital Factory 2050 (DF2050): An industry-led centre for collaborative manufacturing research, technology, and solution development.

- The Innovation Collaboratory (IC): An industry-led centre for manufacturing technology application and process development.

- The Manufacturing Skills Academy (MSA): Scotland’s hub for manufacturing skills and education, linking to existing and future providers.

- The Forum: NMIS’ interface with the wider AMIDS site, providing access to on-site financial advice, business support, and links to external organisations such as schools, Zero Waste Scotland, the Scottish Institute for Re-Manufacture, and the One Scotland Partners.

Stakeholder consultation informed the design at all stages to understand the requirements of the diverse users of the facility. Several key design drivers were identified, particularly for the interior elements:

- Engagement: The design must present a striking and welcoming image to the public, industry, and university stakeholders.

- Flexibility: The interior was planned with a zoned, legible layout and a repetitive building module to allow for easy expansion and accommodate future demands such as new or larger equipment, increased staff, or a bigger building.

- Healthy workplace: The interior should exemplify high-quality, healthy building design and sustainability, operating free of fossil fuels.

What were the biggest specification challenges on the project and how were these overcome?

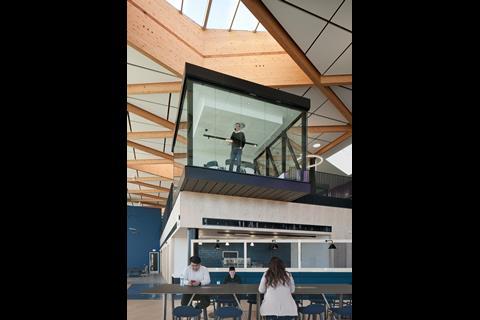

The biggest specification challenge for the project was to design a building that was prominent, instantly recognizable, and distinctly Scottish in character. To achieve this, we chose a vibrant purple cladding for the exterior, reflecting the heather found in the Scottish Highlands. Additionally, we used a visible glulam cross-laminated timber diagrid frame, creating a striking architectural structure.

These exterior elements had to be seamlessly integrated into the interior, combining the colourful palette of the NMIS brand to ensure the building felt inherently part of the brand. We also needed to incorporate the architectural and branding elements with the goal of creating a biophilic and collaborative space for end users.

To overcome these challenges, we developed a warm and welcoming interior palette of materials that allowed for reflective spaces for concentrated work, featuring timber elements, supportive planting, and acoustic treatments for audible comfort. This was harmoniously blended with vibrant brand colours to punctuate collaborative spaces, encouraging discussion and innovation.

What are the three biggest specification considerations for the project type? How did these specifically apply to your project?

Collaboration. One of the primary goals was to design the building as a collaborative space for the university, companies, and entrepreneurs. We provided tools and seating arrangements to foster collaboration, optimizing adjacencies for post-lecture or post-meeting interactions. The design included strategically placed meeting rooms, booths, and fitted furniture. Meanwhile, the lecture theatre was designed with flexible seating to accommodate group settings.

Sustainability. The university aimed for the building to operate without fossil fuels, focusing on passive and other sustainable measures aligned with the RIBA 2030 Targets and we achieved BREEAM Outstanding certification. Internally, we prioritized specifying carbon-neutral products and those manufactured locally, ideally in Scotland. This included using fabrics from Scottish manufacturers, which are showcased throughout the building.

Adaptability and choice. We provided a variety of workspaces to accommodate different work styles and activities, empowering students, staff, and visitors to choose areas that suit their specific needs. The learning landscape included movable and fixed furniture to evolve with occupant needs. We offered hotdesking and touchdown spaces, individual workspaces, and village setups for collaborative work. Meanwhile, a variety of seating options were provided, including stools, task chairs, meeting rooms, and booths. This variety allows staff to choose the type of work setting that suits them best, whether for group work or focused individual tasks, in open or enclosed spaces.

Do you have a favourite product or material that was specified on the project?

We aimed to highlight British and Scottish design throughout the interior, incorporating local manufacturers whenever possible. Notably, we featured Bute Fabrics on all fitted furniture to showcase exemplary Scottish craftsmanship. The chosen fabrics not only highlighted vibrant colours that align with the company branding but also ensured the building felt intrinsically connected to the NMIS identity.

For internal finishes, we selected products from Interface Flooring, which were designed with biophilia in mind and emphasized low carbon footprints. These finishes prioritized recycled materials and acoustic comfort, aligning with our sustainability goals.

Internal planting was provided by GPPlantscape, based in South Lanarkshire, who also collaborated on the construction of a large-scale living wall in the central forum. This feature presented unique challenges due to the diagrid timber structure and the scale of the planting, but it has become a striking and memorable element of the design.

Are there any suppliers you collaborated with on the project that contributed significantly? And what was the most valuable service that they offered?

We presented LSA Projects with a significant challenge regarding the extensive use of timber cladding throughout the interior. The LSA team adeptly tackled this by designing bespoke panelling that seamlessly integrated with services and complemented other finishes and construction elements. Through numerous collaborative meetings with LSA, Morrison Construction, and HLM, we worked together to produce high-quality wall panels with exceptional acoustic properties. The timber linings, which varied in finish and format, covered a substantial portion of the internal walls, particularly around meeting pods and within the Lecture Theatre.

We aimed to highlight British and Scottish design throughout the interior, incorporating local manufacturers whenever possible.

What did you think was the biggest success on the project?

NMIS stands as a highly successful project, poised to drive future development and offer a dynamic space for industry professionals to collaborate. It emphasizes sustainability by achieving Net Carbon Zero operation. The design effectively integrates the Digital Factory and Innovation Collaboratory, creating cohesive office spaces on the ground and upper floors that foster collaboration among engineers, researchers, and academics. The Forum serves as a crucial linking element, providing a valuable resource for both NMIS and the broader AMIDS community, facilitating ongoing collaboration.

A notable achievement of the project is its design flexibility. This is enhanced by an interior that fosters collaboration among universities, companies, and entrepreneurs on innovative short-term projects up to the prototype stage. NMIS’s adaptable internal layout features a modular design and clearly zoned areas, allowing for easy reconfiguration and expansion to meet future demands, such as new equipment, additional staff, or larger facilities. This versatility is evident in the open-plan office space and dedicated meeting areas, accommodating up to 90 research staff, making NMIS a vital hub for industry and academia. It serves as an incubator for small companies and start-ups, offering both office and workshop space for the manufacturing and complementary sectors, thereby driving innovation and growth.

An additional and unique success of NMIS was the opportunity the project provided us to contribute to the surrounding community through our Social Value initiatives. In collaboration with Morrison Construction, we engaged with Renfrew High School students, helping them improve their school environment and giving them the opportunity to design a mural for their playground. Our commitment to the school continues post-project, as we participate in careers days to inspire the next generation of architects and designers.

Project details

Architect HLM Architects

Structural engineer Waterman Group

M&E engineer Davie + McCulloch Ltd

Quantity surveyor MGAC

Project manager Turner & Townsend

Contractor Morrison Construction

Designer and installing sub-contractor for the Glulam and CLT B&K Structures

Our “What made this project” series highlights the outstanding work of our Architect of the Year finalists. To keep up-to-date with all the latest from the Architect of the Year Awards visit here.

No comments yet